News & Events

Unlocking the Potential of IoT and Industry 4.0 with Modern Manufacturing ERP

The emergence of Internet of Things (IoT) technology has enabled the evolution of manufacturing to Industry 4.0, an era where factory equipment can be connected in a networked and automated environment. By enabling data exchange between machines, objects, or systems, this innovation creates an environment where more advanced production systems can be built.

Manufacturing ERP software is the backbone of the new IoT-enabled, Industry 4.0 manufacturing system. It provides a unified platform to coordinate and manage all aspects of the factory operations—from supply chain planning, shop floor scheduling and execution, quality management, to data analytics. With its comprehensive suite of functionalities, ERP enables manufacturers to reap the full benefits of IoT and Industry 4.0 technology.

From an IT perspective, manufacturing ERP allows for better integration with other enterprise systems, such as MES (Manufacturing Execution System), PLM (Product Lifecycle Management) and MRP (Material Requirements Planning). The tight coupling between these systems facilitates the exchange of information, such as real-time production data from the shop floor, product design and engineering changes. This allows manufacturers to realize greater operational efficiency with improved responsiveness to customer requirements.

In addition, ERP software plays an important role in driving digital transformation initiatives in the manufacturing industry. With its ability to manage large volumes of data from multiple sources and provide real-time insights, modern ERP solutions enable manufacturers to improve decision making across all levels of the organization. This ultimately leads to improved customer service, faster product delivery, and reduced operating costs.

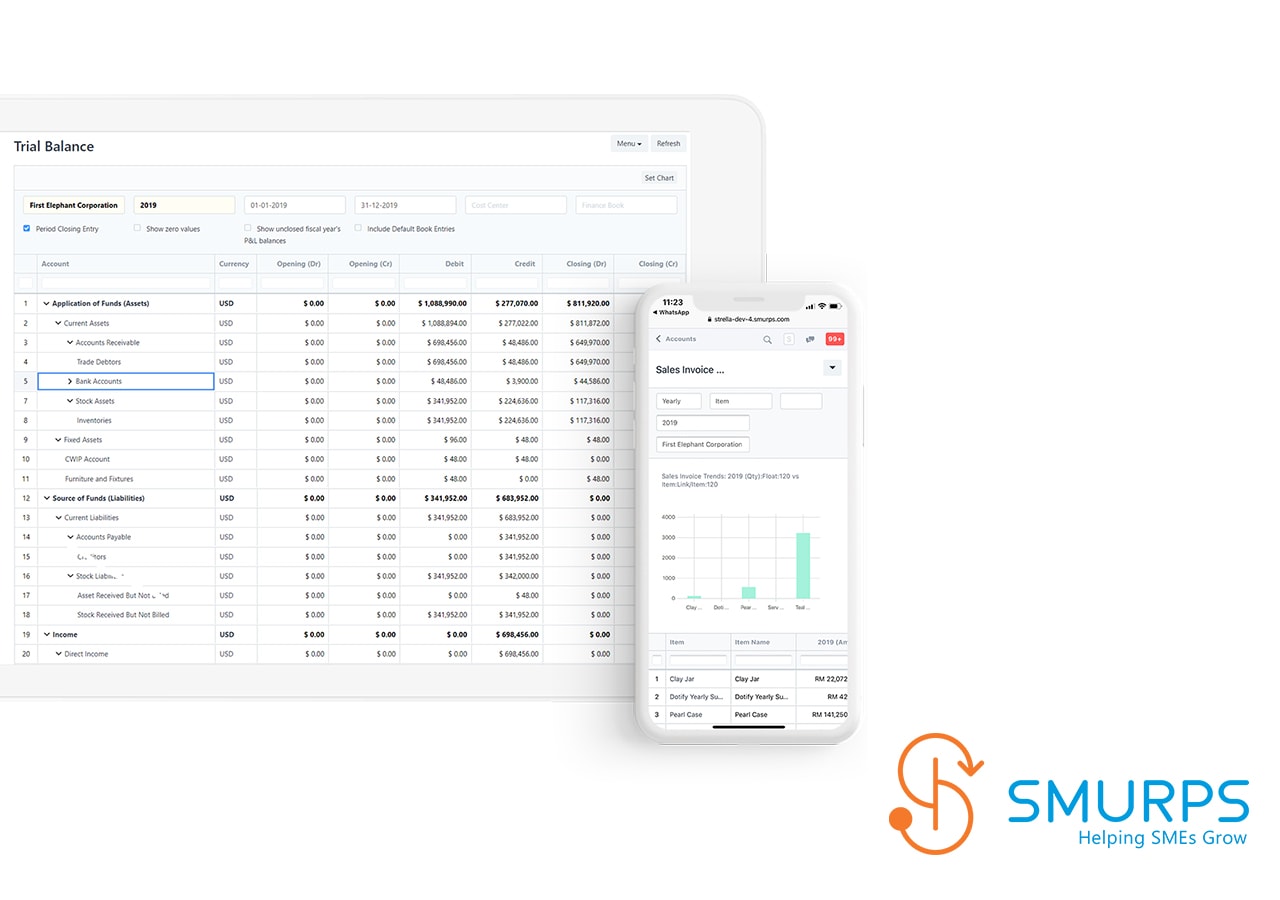

As businesses continue to adopt IoT technology and embrace Industry 4.0, it is essential for them to select an ERP system that provides a comprehensive view of their factory operations. With its powerful suite of features, the SMURPS platform is the perfect choice for manufacturing organizations looking for an integrated platform that connects to IoT and various other Industry 4.0 technologies. The platform provides a comprehensive Manufacturing Solutions package that supports shop floor production activities. It encompasses Work Order management, inventory management, and integration with IoT and production planning tools, ensuring a complete solution for manufacturing needs.

By leveraging additional data analytics capabilities, SMURPS can help manufacturers to identify opportunities for process improvements and uncover new business insights. Moreover, its advanced real-time reporting capabilities provide a clear picture of the production status at any given time. This allows manufacturers to make informed decisions quickly in order to stay competitive in this dynamic industry.

The rise of Industry 4.0 presents a great opportunity for manufacturers to optimize their operations and increase profit margins. With the right ERP system, manufacturers can tap into the power of IoT and Industry 4.0 to unlock their potential and stay ahead in a rapidly changing market. SMURPS is designed to provide everything needed to make the most of this new era of manufacturing excellence.

Necessity or want?

Learn more about how SMURPS can help you unlock the potential of IoT technology and Industry 4.0, and discover how to get the most out of your ERP system for increased productivity, cost savings, and improved customer service. Contact us today to find out more about SMURPS solutions for modern manufacturing.